제품소개

노력하는 기업! 앞서가는 기업!CT-Joint(진공 배관용)

개요 / Overview

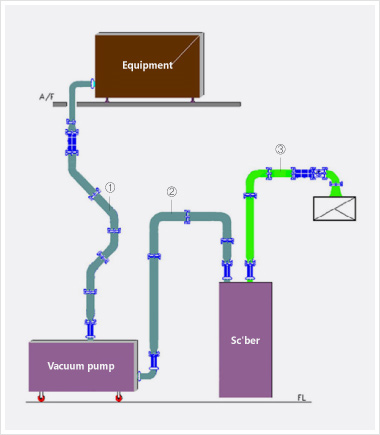

진공 및 배기 배관에 쓰이는 접합 공법으로, 기존기술의 한계인 현장 용접을 극복한 것으로 관을 절단하여 바로 연결할 수 있고 철거 시 재사용 할 수 있는 배관 연결 자재임. 특히 코팅 배관의 용접이 불가능 하거나 후가공이 어려운 곳에 용이하며, 연결이 간편하여 공기 단축 및 원가절감에 효과적임.

A joint construction method used in vacuum and exhaust piping, which will overcome field welding, one of the limits of the existing

technology, can be directly connected by cutting a pipe. A material used in the method will be reusable after it is removed.

In particular, the method is very suitable for difficult places about coating piping welding and post-processing. Joints have an excellent

resistance to corrosion and thanks to easy connectivity, they are highly effective in reducing construction time and costs.

적용범위 / Scope

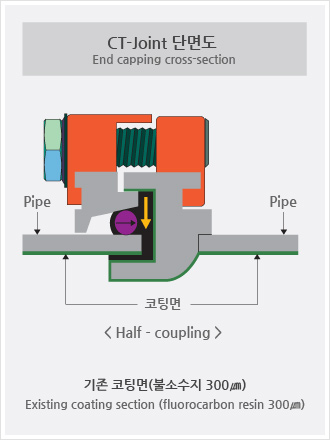

부식 현상 해결 / Resolution for Corrosion

용접이 필요없는 관의 연결 조인트 / Connecting joints of piping which does not need welding

-

- OMF(진공배관용)

- OMF-FLANGE를 기존 MF FLANGE를 개선한 것으로 O - RING을 고정하기 위해 센터링인 내링과 외링없이...

-

- A1-Joint

- 용접 POINT가 1개소, 직각도 유지, 오차범위 허용(±2mm), REVISION시 PIPE직관부 절단만으로 작업이...

-

- A2-Joint

- 현재 반도체, 화학, LCD 배기 LINE 설치시 배관시공 방법으로 FLANGE 용접 방식을 사용하고 있다.

-

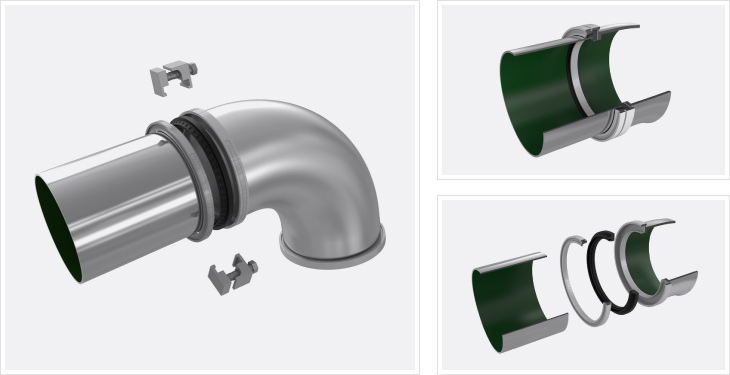

- A3-Joint

- 모든 설비배관에 적용 가능하며 시공이 간편하고, 재사용이 가능하므로 원가절감은 물론 환경...

-

- Lock-Joint

- Lock-Joint는 용접 작업이 어려울 때 pipe만 절단하여 Jointing 하는 방식으로 장비의 PCW(냉각수)LINE...